Horizontal tube honing machine – Lyor M

Merk: Robbi

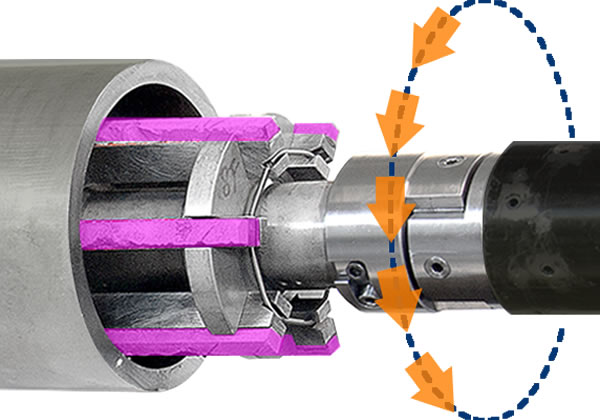

The tubes are clamped on prisms. The hydraulic expansion honing head rotates inside the component.

Aanvraag offerteHorizontal honing machines LYOR are distinguished by their rigidity and power.

- A hydraulic cylinder controls the honing head movement.

- Three phase electric motor controlled by a vector inverter, servo-ventilated controlling the spindle rotation.

- The drive transmission is through a gear-box in which the gears are hardened and ground, projecting high torque and stock removal.

- Programming is very easy with the ‘touch-screen’.

- The visualization of all the working data enables the operator to attend during the working cycle.

Benefits of Contra-rotating component

Remarkable are the benefits of having the contra-rotantibg component being worked against rotating with respect to the honer, including:

- improved roundness and straightness of the bore

- major productivity, especially on small diameter components

- the honing oil is distributed uniformly and constantly in the components, increasing the heat dispersion produced by the honing process. (on machines without rotation, the heat is concentrated on the top part of the component where there is less honing oil).

Technical Specifications |

UM |

40.20 |

40.30 |

40.40 |

40.50 |

40.60 |

40.70 |

|

Bore diameter (Min. – Max.) |

mm. |

20-400 |

20-400 |

20-400 |

20-400 |

20-400 |

20-400 |

|

Max. tube length |

mm. |

2000 |

3000 |

4000 |

5000 |

6000 |

7000 |

|

Max. honing head stroke |

mm. |

3000 |

4000 |

5000 |

6000 |

7000 |

8000 |

|

Number of steady rests for honing head extension |

# |

1 |

1 |

2 |

2 |

2 |

2 |

|

Machine length |

m. |

9 |

11 |

13 |

15 |

17 |

19 |

|

Machine width |

m. |

2,8 |

2,8 |

3,4 |

3,4 |

3,4 |

3,4 |