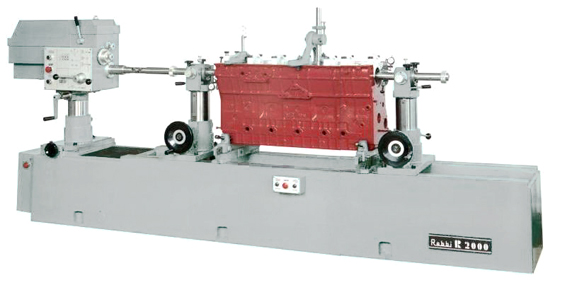

R2000/B

Merk: Robbi

The direct tool setting capabilities provided on the machine minimize operator error.

The line bore’s versatility allows boring of overhead cam type cylinder heads, passenger car blocks, large diesel blocks and a wide range of other industrial uses.

The 4-way adjustment of the boring head and columns simplifies set-up.

The twin control panels puts the operator in front of the work for full control during the boring process.

The infinitely variable spindle selection combined with choice of feed, gives the operator precise control of the bore finish.

Extra long boring spindle travel maximizes the boring capacity with just one tool setting.

Bed

Workpiece setting up

Workhead

Boring Bar Supports

Characteristics

- Complete electric installation with low tension controls (24 V)

- Lighting system

- 1 Precision tool setting micrometer

- 2 Universal centering devices

- 1 Pair of parallel supports 600×100 mm

- 1 Pair of parallel supports 600×230 mm

- 1 Pair of parallel supports 400×140 mm

- 4 Locking clamps

- 1 Complete bridge central support

- 1 Dial gauge holder

- 1 Bearing adjusting device

- 1 Set of spanners

- Operating manual and spare parts list

Machineparts

- Length of block: 1800 mm

- Min Distance from bed to bar center-line: 400 mm

- Max Distance from bed to bar center-line: 800 mm

- Boring diameters wiht bars and cutters heads: 22 – 200 mm

- Speeds of spindle: 0-500 RPM

- Feed manual rapid: 100 mm/giro

- Feed manual micrometric: 0.1 mm/giro

- 2 Automatic feeds: 0,05-0,1 mm/giro

- Max Spindle travel: 430 mm

- Electric motor power: 1,5 kW