- Electric installation 24 V

- Hydraulic installation

- Cooling installation with tank

- Two self centering chucks

- Pair of additional counter weights

- Grinding wheel with pair of wheel hubs

- Narrow steady rest

- Wheel periphery and side truing attachment with diamond

- Eccentricity control device with dial gauge

- Truing fixture for checking concentricity with dial gauge

- V-square for centering of crankpins with dial gauge

- Wheel balancing mandrel

- Motor drive pulley for reduced wheel diameter

- Grinding wheel stripper

- Set of steel splash guards

- Service spanners

- Operating manual

- Set of steel splash guards

- Service spanners

- Operating manual

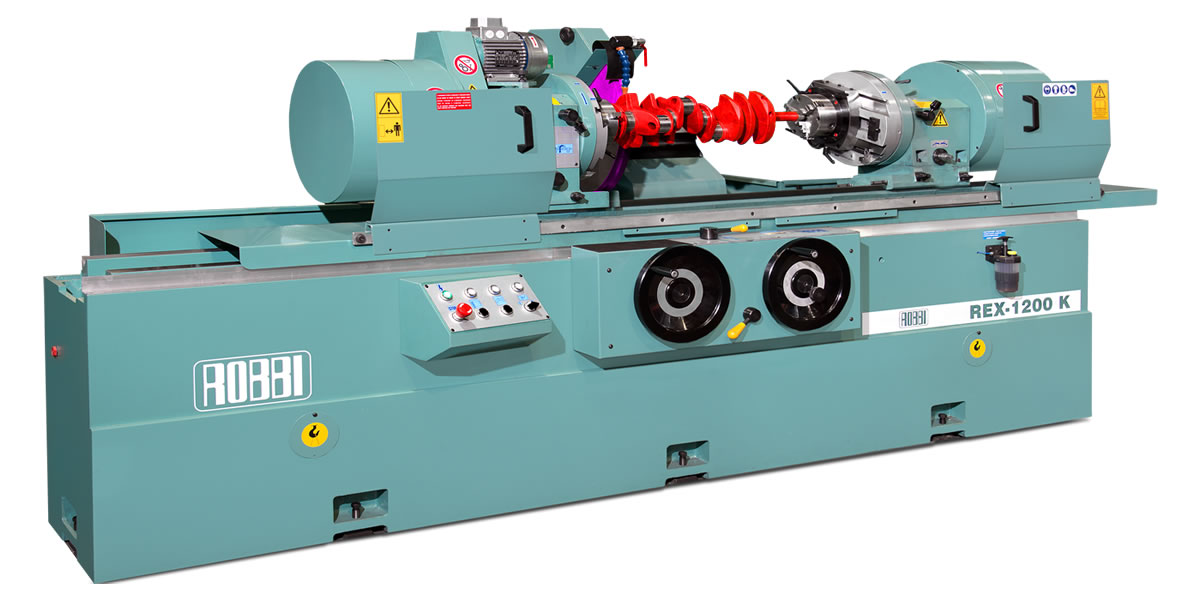

REX 1200

Merk: Robbi

REX Crankshaft Grinders are designed to utilize the most accurate and efficient crankshaft setup system available.

REX Crankshaft Grinders use work heads with 4-way cross slides with an advanced locking system which permits quick centering of the crankshaft.

Heavy duty one piece cast iron construction assures you a lifetime of superior accuracy and dependability.

Whatever your crank grinding needs, REX has a model designed to do the job that your customers demand at a price that you can afford.

Characteristics

Standard Equipment

Machineparts

Technical Specifications

- Distance between centers: mm 1320

- Distance between chucks: mm 1300

- Height of centers over table: mm 220

- Swing over table: mm 440

- Offset of centers: mm 80

- Grinding diameter: mm 180

- Fast hydraulic wheelhead traverse: mm 80

- Hand micrometric wheelhead feed: mm 150

- Hand micrometric wheelhead feed graduation: mm 0,005

- Whellhead feed per reverse: mm 1

- Hand micrometric worktable traverse per reverse: mm 11

- Fast hydraulic worktable traverse: m/ min 3

- Grinding wheel speeds: rpm 100-1150

- Grinding wheel diameter: mm 610

- Width of grinding wheel (min – max): mm 19-50

- Diameter of chucks: mm 160

- Chucks holding diameter: mm 200