s3.5

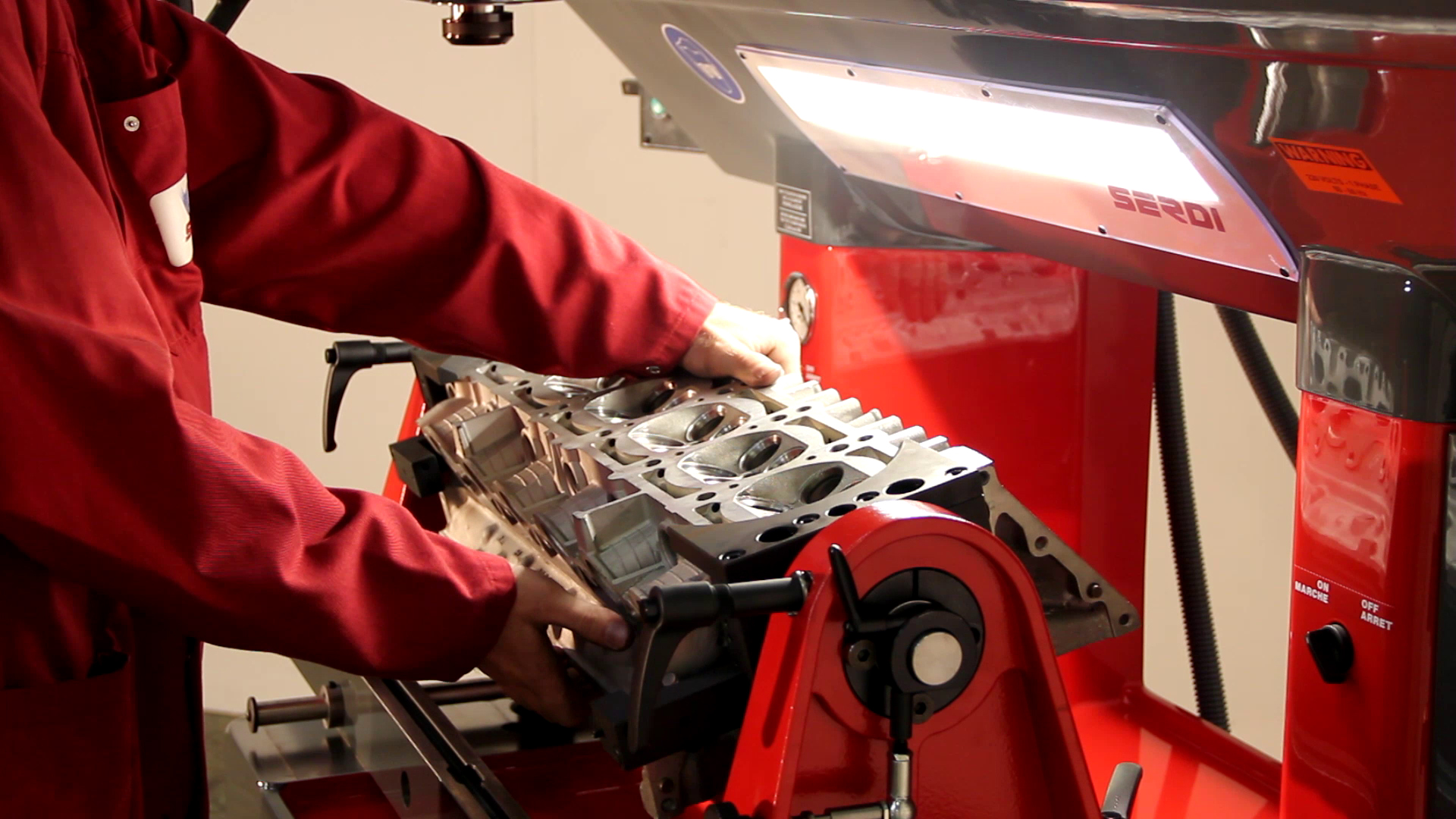

Merk: Serdi

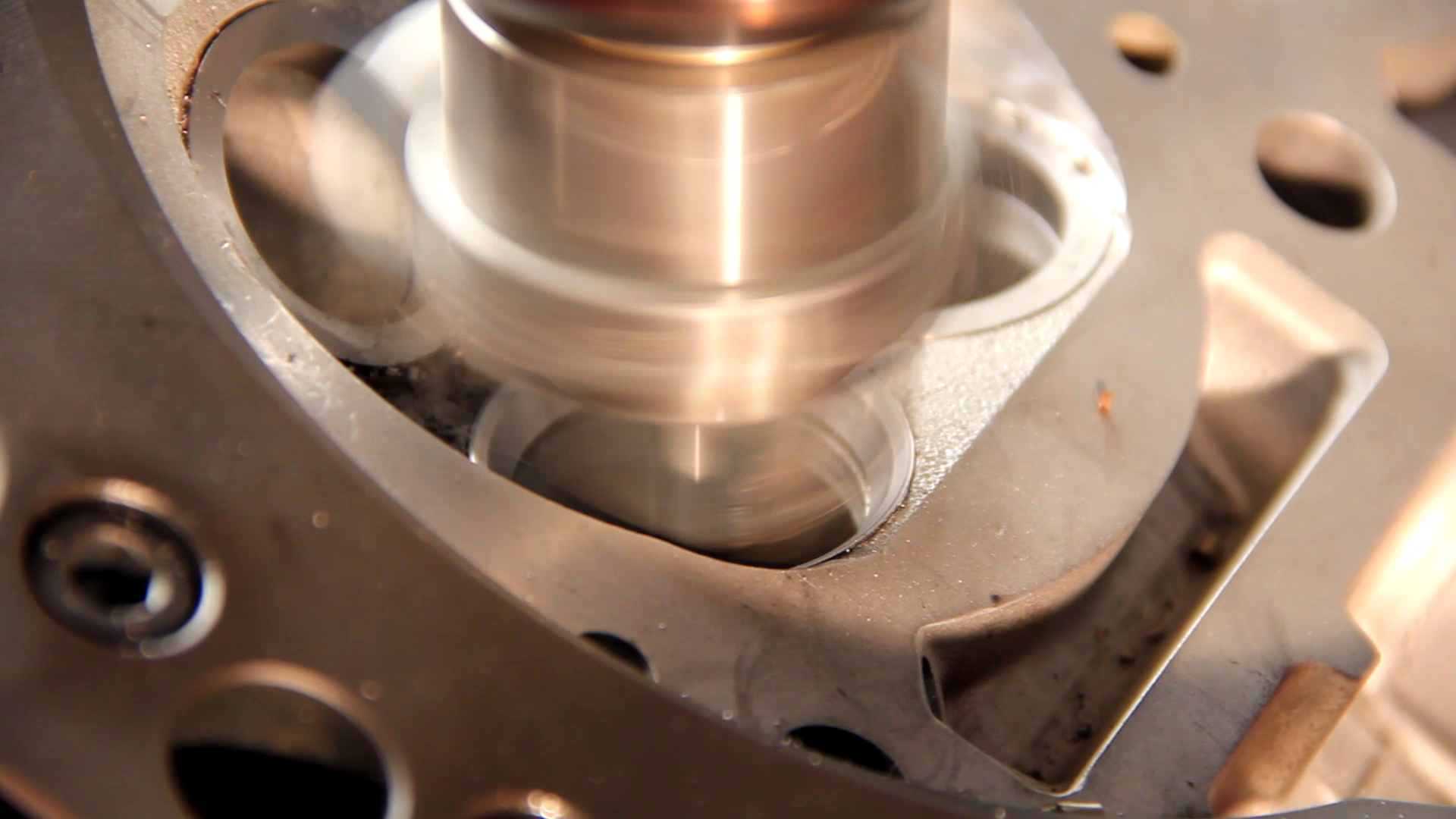

High precision valve seat and valve guide cutting machine especially designed for multi-valve cylinder heads. Patented workhead with triple air-float, patented centering system and built-in spindle motor. Perfect machine for the most demanded motorcycle and automotive multi-valve cylinder heads. Achieves excellent levels of concentricity even in guide sizes as small as 3 mm/0.12”.

Aanvraag offerte Download PDFCharacteristics

- Machining capacity from 16mm to 70mm / 0.6’’ to 2.75’’.

- Patented lightweight workhead : built-in spindle motor and triple air-float centering system.

- Minimal workhead inertia and maximum floatation for unmatched centering sensitivity.

- Fully integrated spindle motor, variable speed from 100 to 1200 RPM, paired to a 1.5 kW Siemens inverter.

- Forward and reverse directions. Extremely wide torque ratings from lowest RPM with constant torque spindle rotation.

- Digital spindle speed rotation and machining depth read out.

- Modern modular machine bed design for improved rigidity, using iron casting parts to get chatter free valve seat machining.

- Manual front-to-back displacement of the cylinder head with pneumatic locking.

- Available with a dedicated tool bit sharpener and a 360° roll over fixture.

- LED worklight.

- Supplied with the new SERDI tooling that decreases the cutting force by 30%, this machine will cut the hardest seats.

Machineparts

- Machining process : Profile cutting bit

- Machining driving : Manual

- Industry : Small and medium production

- Cylinder head type : Motorcycle and automotive multi-valve cylinder heads

- Seat capacity: Ø16 to Ø70 mm / 0.6’’ to 2.75’’

- Centering technology: Triple air cushion centering