s4.5

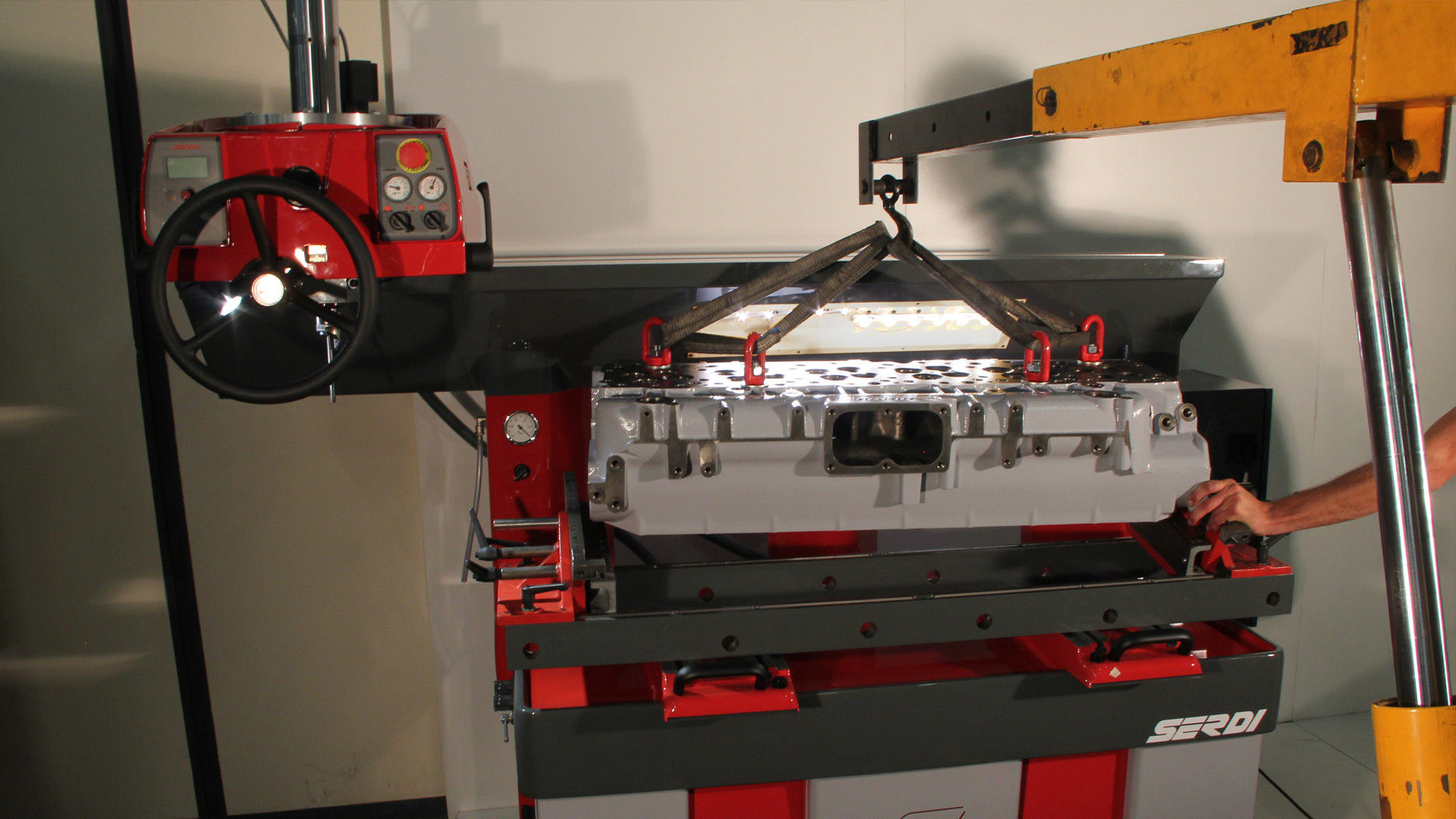

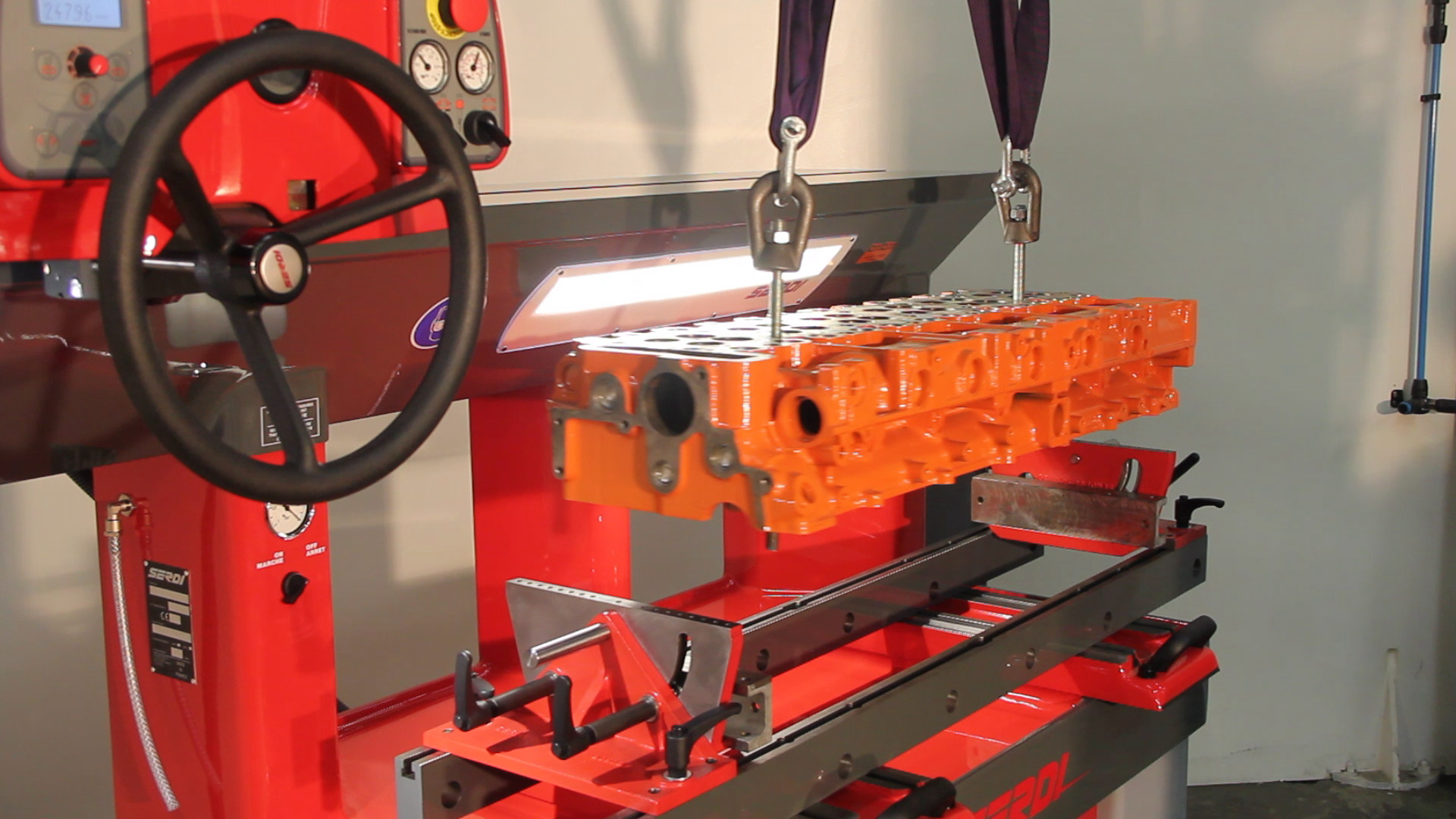

Merk: Serdi

Very accurate, all-purpose machine to ream the guides and cut the valve seats. Triple air-float patented centering system and powerful spindle with built-in motor. Highly versatile machine producing an accurate machining of the valve seats from the smallest to the biggest diameter. This machine can repair any existing engine, from the microengine up to the big stationary engine. The light-weight floating assembly can machine cylinder heads with guide diameters as small as 4 mm ( 0.16’’).

Aanvraag offerte Download PDFCharacteristics

- Machining capacity from 16mm to 120mm / 0.6’’ to 4.72’’.

- Patented lightweight workhead : built-in spindle motor and triple air-float centering system.

- Minimal workhead inertia and maximum floatation for unmatched centering sensitivity.

- Mechanical clamping of the work head on the machine bed with pneumatic clamping jack and vacuum system.

- Fully integrated spindle motor, variable speed from 40 to 800 RPM, with sensorless Vector Flux Control. Forward and reverse directions. Extremely wide torque ratings from lowest RPM with constant torque spindle rotation.

- Digital spindle speed rotation and depth read out.

- Modern modular machine bed made of iron cast, designed for improved rigidity. Computer enhanced static and dynamic characteristics provide the latest in machining technology.

- Fully pneumatic machine.

- Fitted with the new SERDI tooling that decreases the cutting force by 30%, this machine will cut the hardest seats.

Machineparts

- Machining process : Profile cutting bit

- Machining driving : Manual

- Industry : Small and medium production

- Cylinder head type : From the micro engine to the big stationary engine

- Seat capacity: Ø16 to Ø120 mm / 0.6’’ to 4.72’’

- Centering technology: Triple air cushion centering