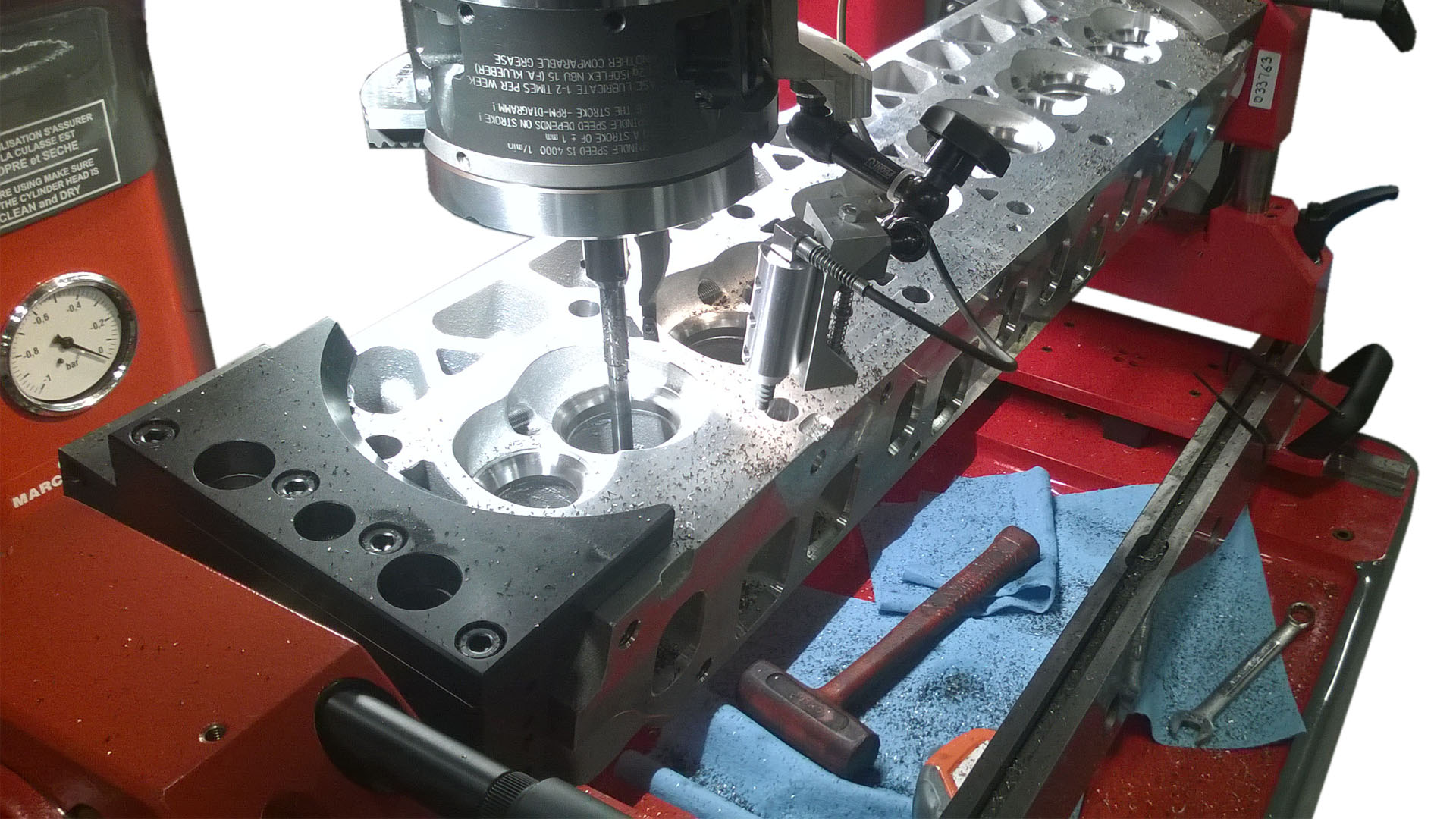

STroniK M

Merk: Serdi

Machine working by interpolation between the cutting tool radius and spindle axis. The single point cutting tool generates the profile of the valve seat through an integrated design system, using radius and straight segments. Machine specifically appropriate for machining of racing engines, or engine prototyping.

Aanvraag offerte Download PDF Product filmCharacteristics

- Single point seat cutting machine with Z and U axes CNC digitally controlled.

- U axis carriage controlled by induction motor can reach a cutting feed rate up to 300 mm/min.

- 4 kW built-in spindle motor, variable speed from 0 to 3000 RPM. High machining accuracy even at low speed due to total lack of mechanical transmission.

- Intake and exhaust seats can be performed simultaneously without tool holder changes.

- Machining capacity from 20mm to 163mm / 0.78’’ to 6.42’’.

- Patented lightweight workhead : built-in spindle motor and triple air-float centering system. Minimal workhead inertia and maximal floatation for unmatched centering sensitivity.

- Vacuum clamping of the work head on the machine bed.

- Modern modular machine bed design for improved rigidity. Computer enhanced static and dynamic characteristics provide the latest in machining technology.

Machineparts

- Machining process : Single point

- Machining driving : Half-automatic

- Industry : Small and medium production, engine prototyping

- Cylinder head type : Motorcycle and automotive multi-valve cylinder heads

- Seat capacity: Ø14 to Ø124 mm - .55’’ to 4.66’’

- Centering technology: Triple air cushion centering