R100G

Brand: Elettrorava

Horizontal axis balancing machines are normally used for dynamic balancing of various type of rotors, such as crankshafts, electric motors, machine tool spindles, drive shafts, fans and blowers, large paper rolls, rotors of agricultural machines, and they are also known as “universal balancing machines”.

Most of the modern horizontal axis machines have hard bearing force measuring pedestals, structurally designed so that the rotational frequency during balancing is less than a third of the resonance frequency of the rotor mounted on the machine pedestals.

As a consequence the vibration of the pedestals during rotation is minimal and two very robust and reliable piezoelectric force transducers measure the centrifugal force generated by the unbalance. The machine is therefore permanently calibrated in grams, independent of the rotor mass and its rotation speed, provided that these parameters are kept within the limits specified by the manufacturer.

It is extremely simple to achieve the unbalance indication immediately in grams directly at the first run without the need for trial runs with known unbalances. The operator merely enters into the electronic measuring unit the geometrical dimensions of the rotor, that is the distance between the correction planes and the pedestals and the correction radii.

Characteristics

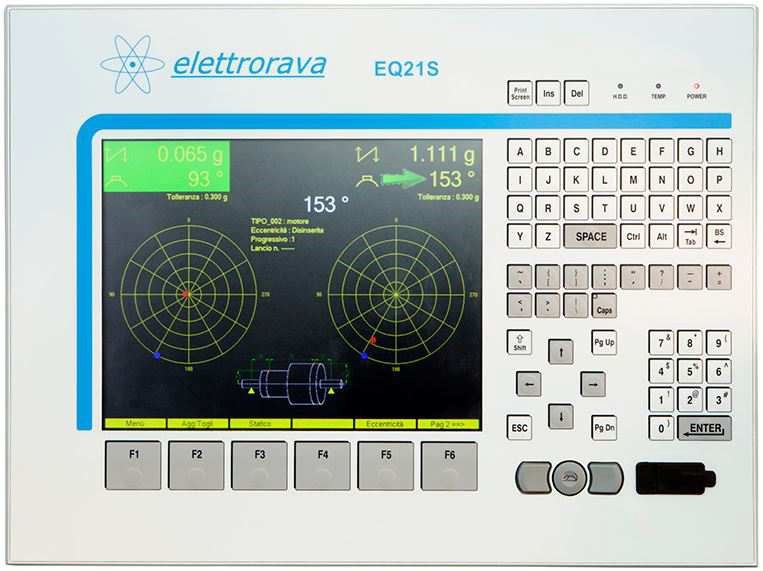

Horizontal balancing machine for balancing of rotor with a mass of up to 100 kg, with force measuring hard bearing pedestals. The rotor driving system is by means of a twin cardan joint connected on the same axis at one end of the rotor. A disc with a graduated scale between 0° and 359° allows an easy and rapid search the angular position of the unbalance. The machine is equipped with the EQ21S electronic measuring unit.

Machineparts

TECHNICAL DATA

- Nominal capacity: 100 Kg

- Maximum weight for symmetric rotor: 150 Kg

- Maximum diameter: 800 mm

- Journals diameter: 10-70 mm

- Maximum sensitivity: 0,5 g mm