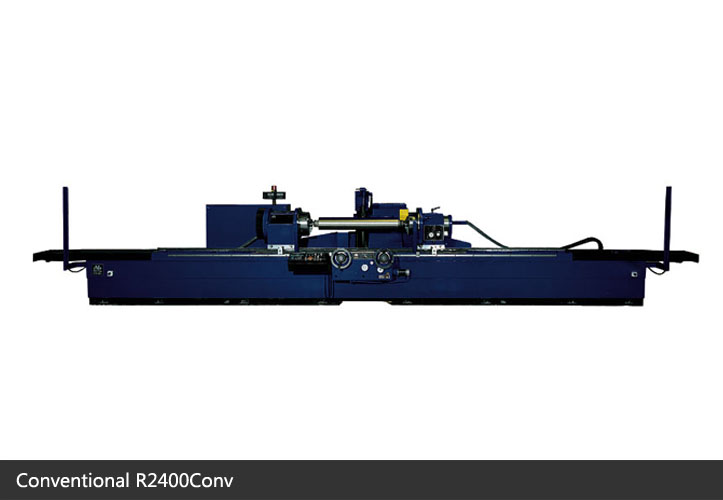

R2400 Conventional

Brand: AMC Schou

The AMC-SCHOU cylindrical grinding machines are used in industries demanding the highest degree of accuracy and productivity. Manufacturers seeking higher levels of precision, smoother surface finishes, and greater overall productivity can achieve significantly improved performance by utilizing AMC-SCHOU’s cylindrical grinders.

Request quoteCharacteristics

- Travelling table design ensuring stability and accuracy for decades.

- The machine is operated through the control panel and hand- and finger wheels on the apron. Table movement can be alternated between single and continuos operation. Both table and wheelslide are regulated with infinitely variable speeds.

- The machine is designed for high precision grinding of straight cylindrical parts, small tapers and multiple diameters.

- Table and variable headstock rotation have a digital read-out as standard. As an option the machine can be equipped with automatic infeed.

- Siemens headstock servomotors offering variable speed, high accuracy, low vibration and large torque also at low speeds.

- Extremely reliable hydraulic system for movements of table and wheelslide ensuring the ground surface will be the same all over the workpieceSKF bearings in heavy-duty design inhead- and tailstock ensuring smooth and trouble free rotation of even extra heavy work pieces.

- Hydrodynamic grinding wheel spindle ensuring no vibrations and no wear as the spindle is rotating on an oiled film. Runout less than 0.001 mm.

- All main components are made of high quality castings from well-established foundries. These are specially processed to avoid any internal stresses in the material ending up in machines that are entirely free of vibrations.

- Simple, stable design with very few movable components resulting in next to no downtime at all do to mechanical problems. Great savings on maintenance costs, as maintenance is limited to cleaning and lubrication alone.

Machineparts

- Max. distance between chucks: 2450mm, 96 inch

- Max. distance between centres: 2400mm, 94 inch

- Max. swing over table: 680mm, 27 inch

- Max. weight of workpiece between chucks: 2500kg, 5510lbs

- Max. grinding length: 2400mm, 94 inch

- Max. grinding diameter with new grinding wheel:610mm, 24 inch

- Table speeds: 30-4000mm/min, 1.2-157inch/min

- Headstock spindle speeds, variable: 5-500 rpm

- Headstock motor: 7kW, 9.5 hp

- Grinding wheel motor: 15 kW, 20hp

- New grinding wheel diameter: 813mm, 32 inch

- Max. grinding wheel width: 100mm, 4 inch

- Diameter of grinding wheel bore for hub: 305mm, 12 inch

- Max. tailstock quill: 70mm, 2.8 inch

- Working space (working machine): 7800x2900mm, 307x114inch

- Net weight of basic machine: 5300kg, 11684lbs

- Gross weight of basic machine: 6300kg, 13889lbs