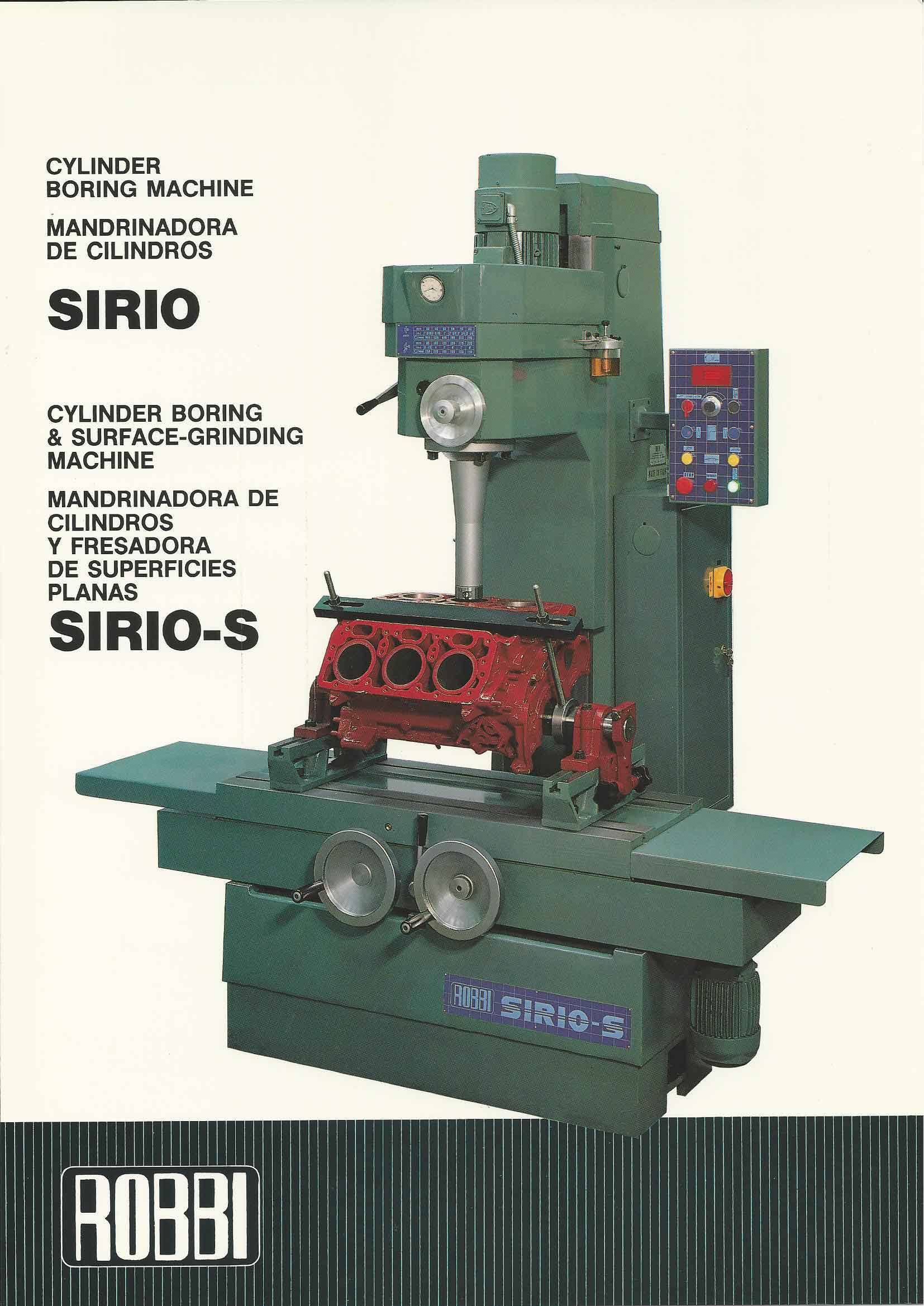

Suitable for engine blocks of cars and trucks medium. Equipped with variable speed range of spindle rotation

Characteristics

Standard Equipment

- Complete electric equipment with control at low tension.

- Spindle motor speed variable control

- 2 setting up supports 100 mm high with bolts

- 2 setting up supports 200 mm high with bolts

- 4 locking clamps with bolts

- Boring infeed control system

- Centering system

- Set of spanners

- Operating manual

Extra Equipment

Tool grinding device (electric motor included), abrasive wheel, diamond wheel, grinding jig

Boring spindle for ø 31 ÷ 160 mm, complete with tool setting micrometer, cutting tools with holders, centering device

Fixture for fat cylinder clamping

Universal fixture for V engine clamping

Universal fixture for cylinder liner clamping

Fixture for motorcycle cylinder clamping

Special milling and drilling spindle Morse taper N3

Micrometric devices for measuring cylinder bores – range 30÷200 mm

Machineparts

Technical Specification

- Boring diameters with standard spindles Min: 31 mm

- Max: 180 mm

- Boring depth Max: 460 mm

- Distance table to head Max: 1260 mm

- Min: 430 mm

- Distance spindle centre to column guides: 340 mm

- Vertical head stroke Max: 830 mm

- Spindle rotation speed: 0 ÷ 500 r.p.m.

- Automatic head feeds (variable): 0,09 – 0,18 mm/rev.

- Useful dimensions – Lenght: 1200 mm

- Useful dimensions – Width: 400 mm

- Longitudinal table stroke: 980 mm

- Traverse table stroke :80 mm

- Automatic longitudinal table feed variable: 0 ÷ 150 mm/min

- Spindle rotation: 2 kW

- Fast head feed: 0,75 kW

- Automatic longitudinal table feed variable: 0,75 kW

- Tool grinder: 0,5 kW

- Lenght: 1800 mm

- Width: 1200 mm

- Height: 2170 mm

- Lenght: 2780 mm

- Width: 1250 mm

- Height: 2570 mm

- Net weight: 1600 kg