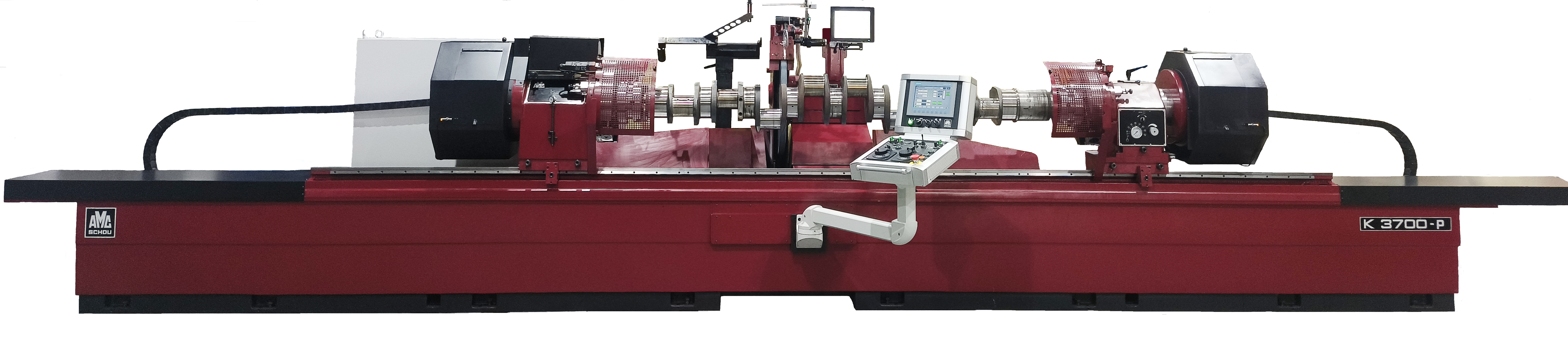

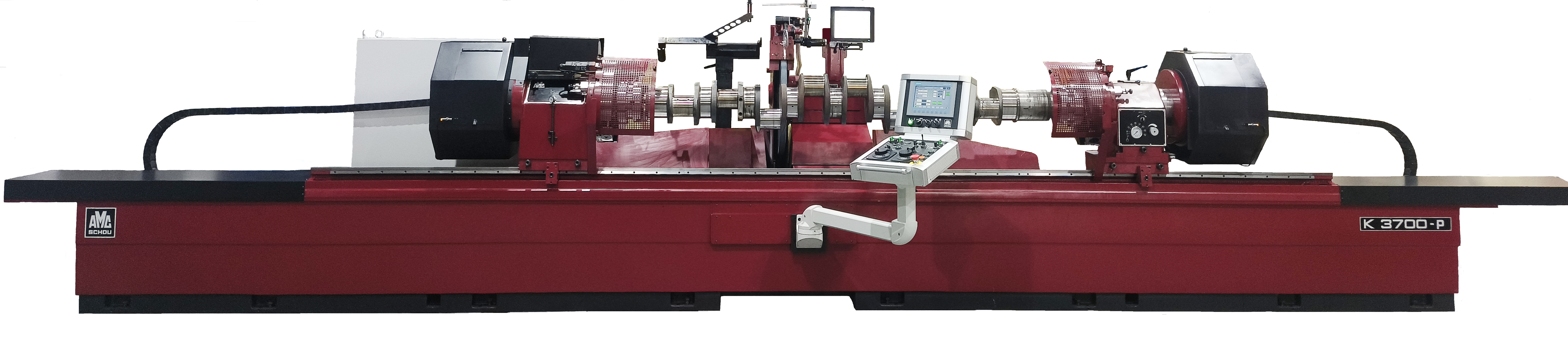

K-2700CNC Crankshaft Grinding Machine

Capacity: 2750 mm (108")

Swing over table: 690 mm (27")

Stroke: twice off-set of centres 280 mm (11")

Colour: red Graduation: mm or inch

(Picture is not the exact machine)

K-2700CNC complete with above standard equipment

1 electric installation for 400 volts, 3 phase AC, 50 cycles + 0 cable

1 grinding wheel motor 7.5 kW

1 electric motor for hydraulic power station 1.1 kW

1 coolant pump 0.12 kW

1 crank centering V-gauge with dial indicator

1 set-up indicator with dial gauge

1 steady rest, standard

1 heavy duty rest standard, range from 30 – 180 mm

1 wheel dresser on the headstock for face, side and radius dressing

3 diamond tipped dressing tool, 0.75 ct.

1 grinding wheel 813 mm (32") x 203.2 mm (8") x 25 mm (1")

1 grinding wheel hub with balancing arbor

1 lifting hook for grinding wheels

1 complete coolant arrangement with tank, hoses and nozzles

1 set of splash guards and spanners

1 measuring device with probe system for measuring for find position of workpiece

1 operating manual and spare parts catalogue

DESCRIPTION OF THE MACHINE WITH STANDARD EQUIPMENT:

BED

One piece cast iron

Alignment by means of a number of adjusting screws

Guide ways protected by telescopic guards

TABLE

Surface with 10Åã inclination

Guide ways with antifriction coating

Guide ways lubrication with lubricate rollers and oil pocket fed from an oil pump

Rack and pinion gear for head- and tailstock movement

Movements performed by means of SKF 50 mm (1.97”) ball screw with pre-loaded ball nut.

Movement performed by means of a SIEMENS 1FK7+S120 3,3 kW 10.5 NM.

Speed 5 to 4000 mm/min. (0.2”-197”)

HEADSTOCK

Rigid spindle with . 170 mm (6.7”) SKF NN-double row bearing

Movement performed by means of a SIEMENS 1FL6+V90PN servo motor 7,0 kW (33. NM)

Setting-up system comprising two throw heads with 190 mm (7.") chucks

(indexing for every 30Åã and 72Åã) incl. jaws with 254 mm capacity, ball screw for throw head movement

Index pins, manual operated

AMC-SCHOU CRANKSHAFT GRINDING MACHINE,

MODEL K-2700CNC - SIEMENS CNC CONTROLLED

1 Packing for shipping

28 Price list no. 165

TAILSTOCK

Rotating spindle with . 170 mm (6.7”) SKF NN double row bearing

setting-up system comprising two throw heads with 190 mm (7.") chucks

incl. jaws with 254 mm capacity, one centre with back plate, ball screw for throw head movement.

70 mm (2.7”) hydraulically operated quill, adjustable centre pressure

Side adjustment Å} 2 mm, controlled by a 40 mm (1.57”) dial gauge

Locking pin for non-rotation of spindle for working with centres

WHEELSLIDE

Guide ways with antifriction coating

Guide ways lubrication fed from an oil pump

Movement performed by means of 40 mm (1.57”) SKF ball screw with pre-loaded ball nut

with SIEMENS servo motor drive 1FK7+S120 3,3 kW 10.5 NM.

Speed 5 to 3000 mm/min. (0.2”-118”)

GRINDING WHEEL HEAD

Hardened spindle runs in the grinding wheel end in a tapered adjustable and hand scraped

sleeved bronze bearing of heavy duty design

At pulley end pre-loaded high precision angle contact bearings are used

The grinding spindle is driven by AC motor, with variable speed 500-800 rpm.

GRINDING WHEEL GUARD

Grinding wheel guard for protection of the 813 mm (32”) grinding wheel with a max.

width of 63.5 mm (2,5”)

GRINDING WHEEL HUB

A grinding wheel hub 12" (305 mm) dia. with clamping width 19 – 63.5 mm (0.75” – 2.5”)

3 pcs. adjustable balancing arbours

Rapid wheel change system

ELECTRICAL SYSTEM

Detached relay box

Cabinet for power supply 400 volts 3 phase, 50 cycles + 0 cable

24 volt DC for control of circuits

Plug-in relays with thermal overload protection

Built-in ventilation for cooling of electrical equipment

CNC-CONTROL

3-axes Sinumeric 840D SL CNC-control, X, Z and C-axes

Swivelling operator panel with a 300 mm (12”) color display

2 electric hand wheels for X- and Z-axes

Simultaneous control of X and Z

For B2B customers, please register here for EU VAT exemption.