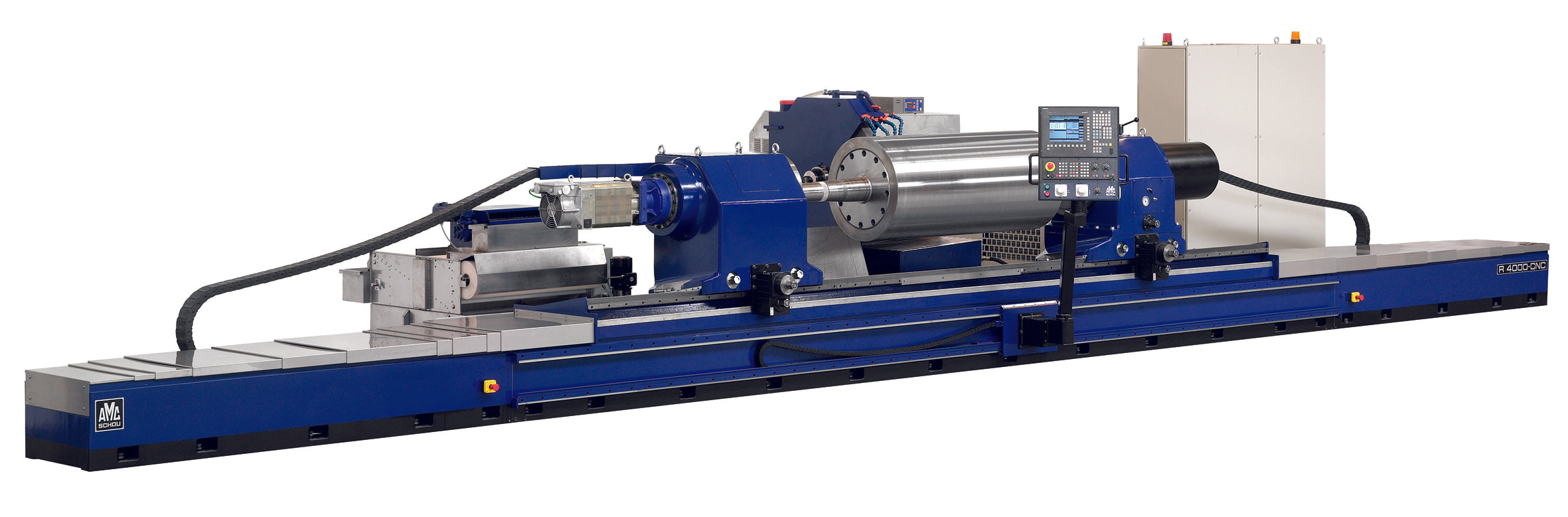

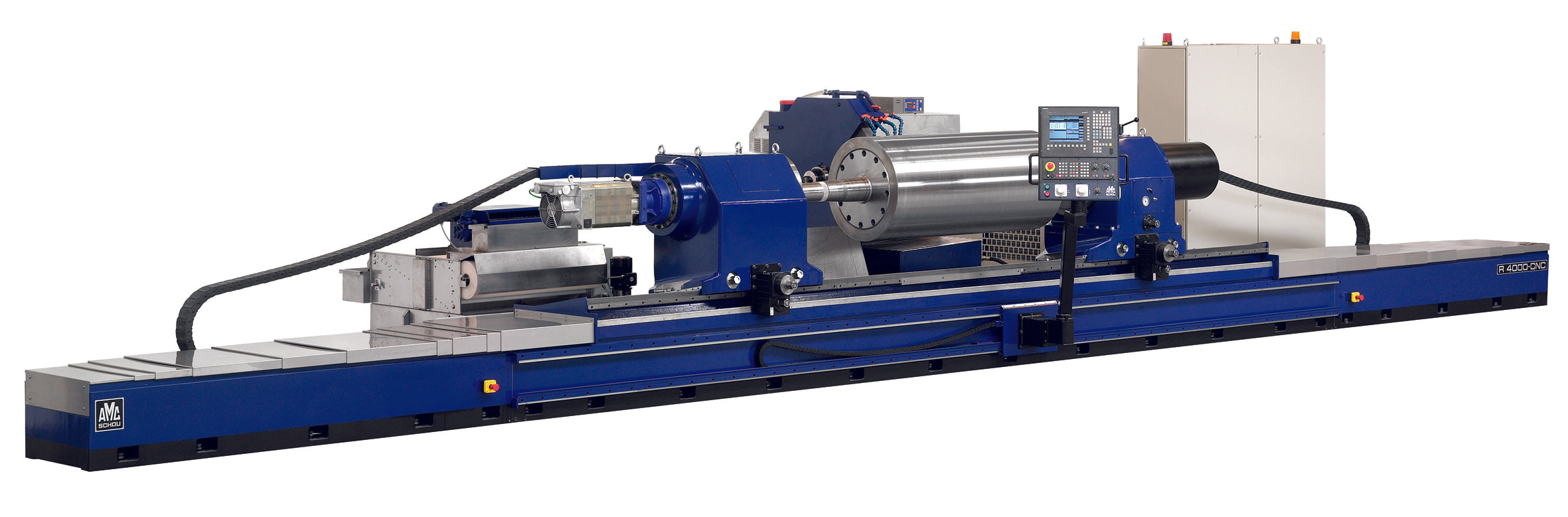

R-4000CNC MD CNC Controlled Cylindercal Grinding Machine

AMC-SCHOU R-4000CNC MD Cylindercal Grinding Machine

(Image may differ from actual product)

|

SPECIFICATIONS: |

||

|

Maximum workpiece length: |

4100 mm |

(161") |

|

Maximum workpiece diameter: |

1200 mm |

(47") |

|

Maximum grinding diameter: |

1200 mm |

(47") |

|

Maximum workpiece weigh |

5000 kg |

(11000 lbs) |

|

Power supply: |

3 x 400 V, |

|

|

50 cycles + 0 cable |

||

|

Colour: |

Blue RAL 5013 |

|

|

Graduation: |

mm or inch |

|

|

BED |

||

|

Cast iron |

||

|

Alignment by means of a number of adjusting screws |

||

|

No pressure lubrication rolling system with automatic filling of oil pockets |

||

|

Guide ways protected by telescopic guards |

||

|

Electrical indicator for low oil level and inspection window on tank for used oil |

||

|

TABLE |

||

|

Cast iron |

||

|

Surface with 10° inclination |

||

|

Guide ways with antifriction coating |

||

|

Rack and pinion gear for head- and tailstock movement |

||

|

Movement performed by means ball screw with pre-loaded ball nuts with servomotor drive |

||

|

for SIEMENS digital converter system |

||

|

Speed 1 to 3000 mm/min. (0.004 - 118 inch/min) |

||

|

HEADSTOCK |

||

|

Movement performed by means of a Siemens main spindle servo motor |

||

|

for Simodrive digital converter system, range 1-140 r.p.m. |

||

|

Hub prepared for fitting chucks |

||

|

Morse taper No. 6 hole in the spindle for dead or live centres |

||

|

TAILSTOCK |

||

|

Rotating or stationary spindle |

||

|

Hub prepared for fitting chucks |

||

|

Hydraulically operated quill traverse, adjustable centre pressure |

||

|

Locking pin for non-rotation of spindle for working with centres |

||

|

Morse Taper No. 6 hole in the spindle for dead or live centres |

||

|

WHEELSLIDE |

|

Guide ways with antifriction coating |

|

No pressure lubrication rolling system with automatic filling of oil pockets |

|

Movement performed by means of a ball screw with pre-loaded ball nuts with servomotor drive for |

|

Simodrive digital converter system |

|

Speed 5 to 2000 mm/min. (0.2”-79”) |

|

Linear transducer for X-positioning secured against dust by overpressure |

|

GRINDING WHEEL HEAD |

|

Hardened spindle runs in the grinding wheel end in a tapered adjustable and hand scraped |

|

sleeved bronze bearing of heavy-duty design |

|

At pulley end pre-loaded high precision angle contact bearings are used |

|

The grinding spindle is driven by AC motor |

|

GRINDING WHEEL GUARD |

|

Grinding wheel guard for protection of the maximum size grinding wheel Ø1200 mm with a max. |

|

with a max. width of 70 mm (2.75”) |

|

GRINDING WHEEL HUB |

|

A grinding wheel hub 12" (305 mm) dia. with clamping width 25 – 70 mm |

|

3 pcs. adjustable balancing arbours |

|

Rapid wheel change system |

|

CNC-CONTROL |

|

3-axes Sinumeric 840D SL CNC-Control, X, Z and C-axes |

|

Swivelling operator panel with a 26.5 cm (10.44") color display |

|

2 electric hand wheels for X- and Z-axes |

|

Simultaneous control of X, Z and C-axes |

|

Back-up com port |

|

SOFTWARE (AMC-SCHOU) |

|

1 program for cylindrical/taper grinding |

|

1 program for sine curve grinding (convex & concave) |

|

1 program for radius grinding (convex & concave) |

|

1 program for dressing |

|

LITERATURE |

|

1 Operating manual with spare part section |

|

1 Packing list |

|

EUR |

For B2B customers, please register here for EU VAT exemption.