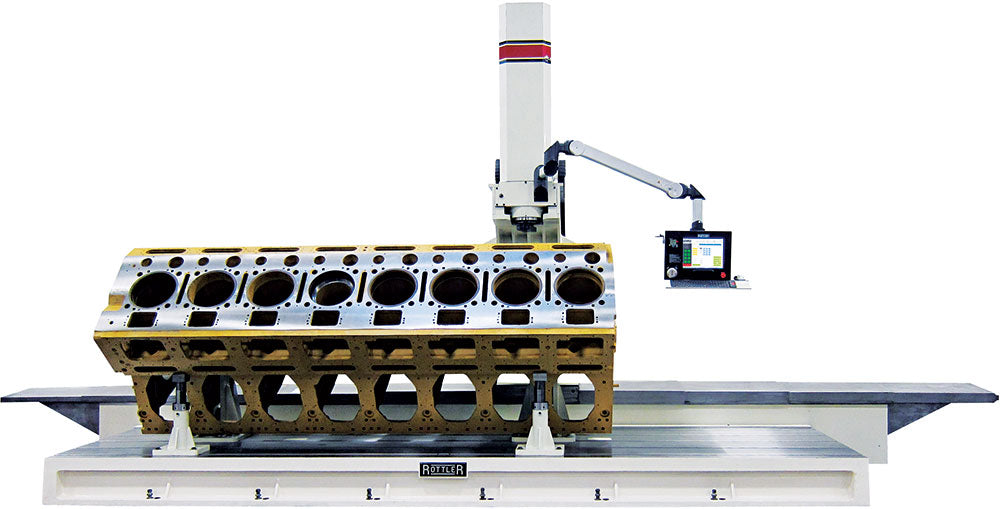

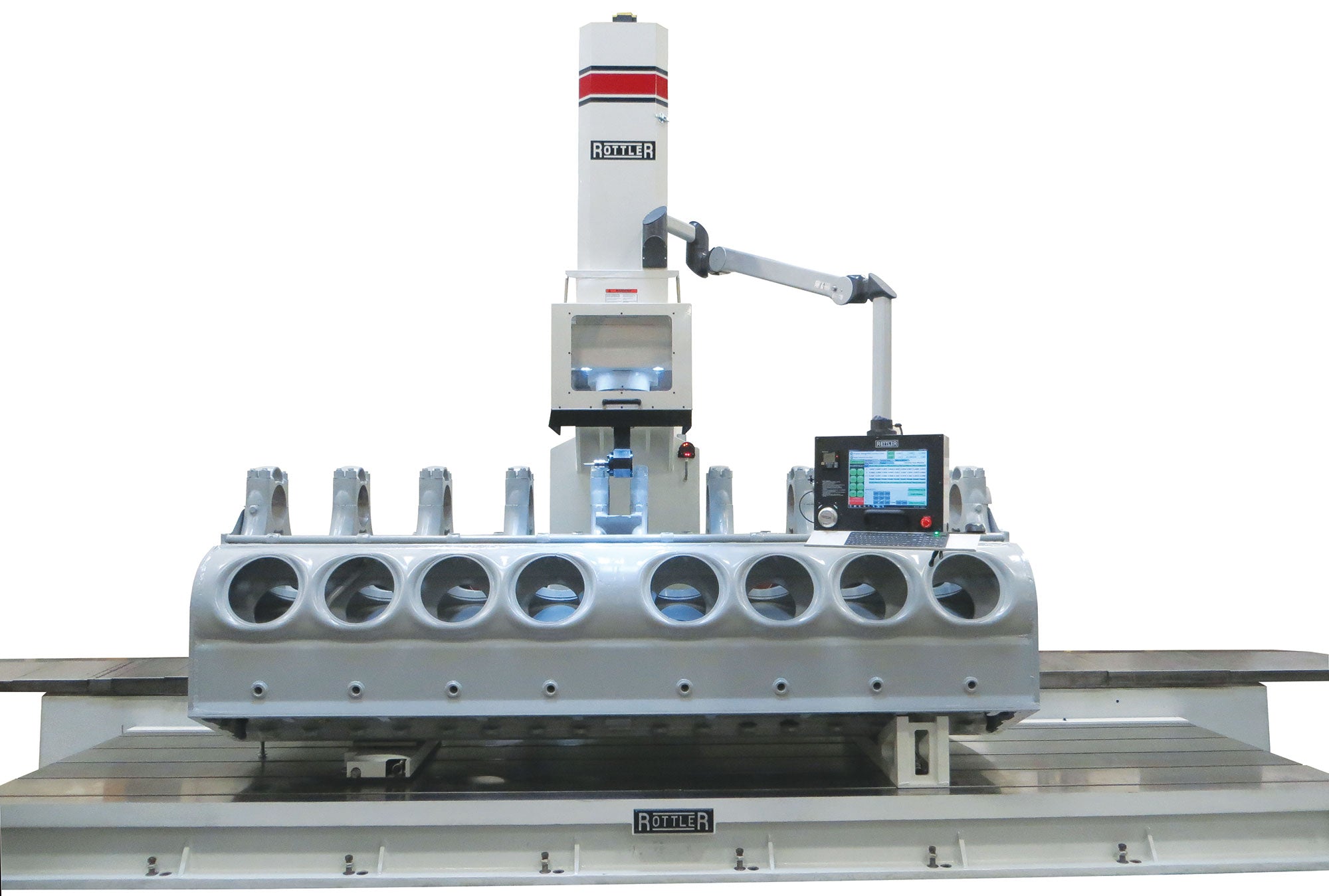

EM109H

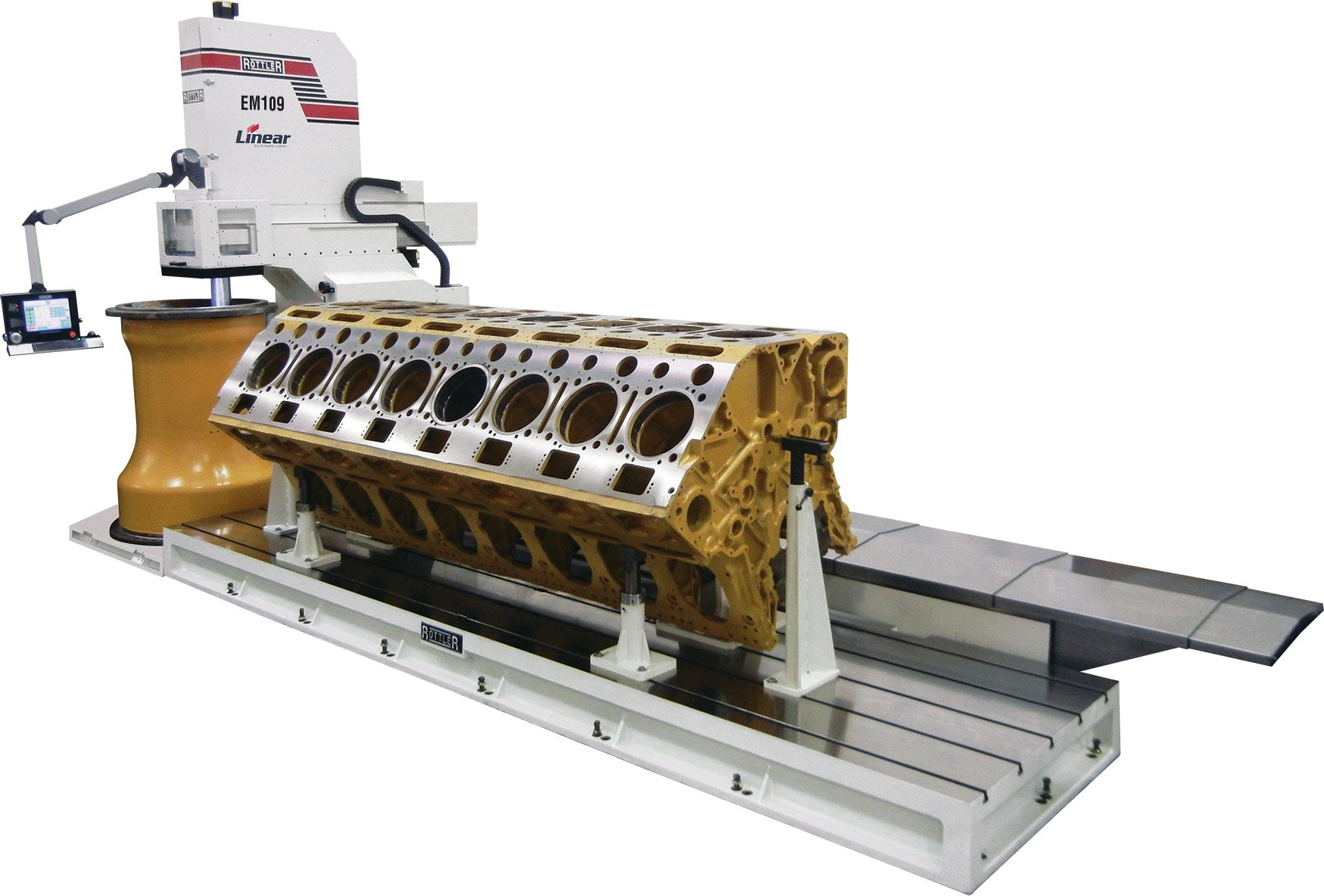

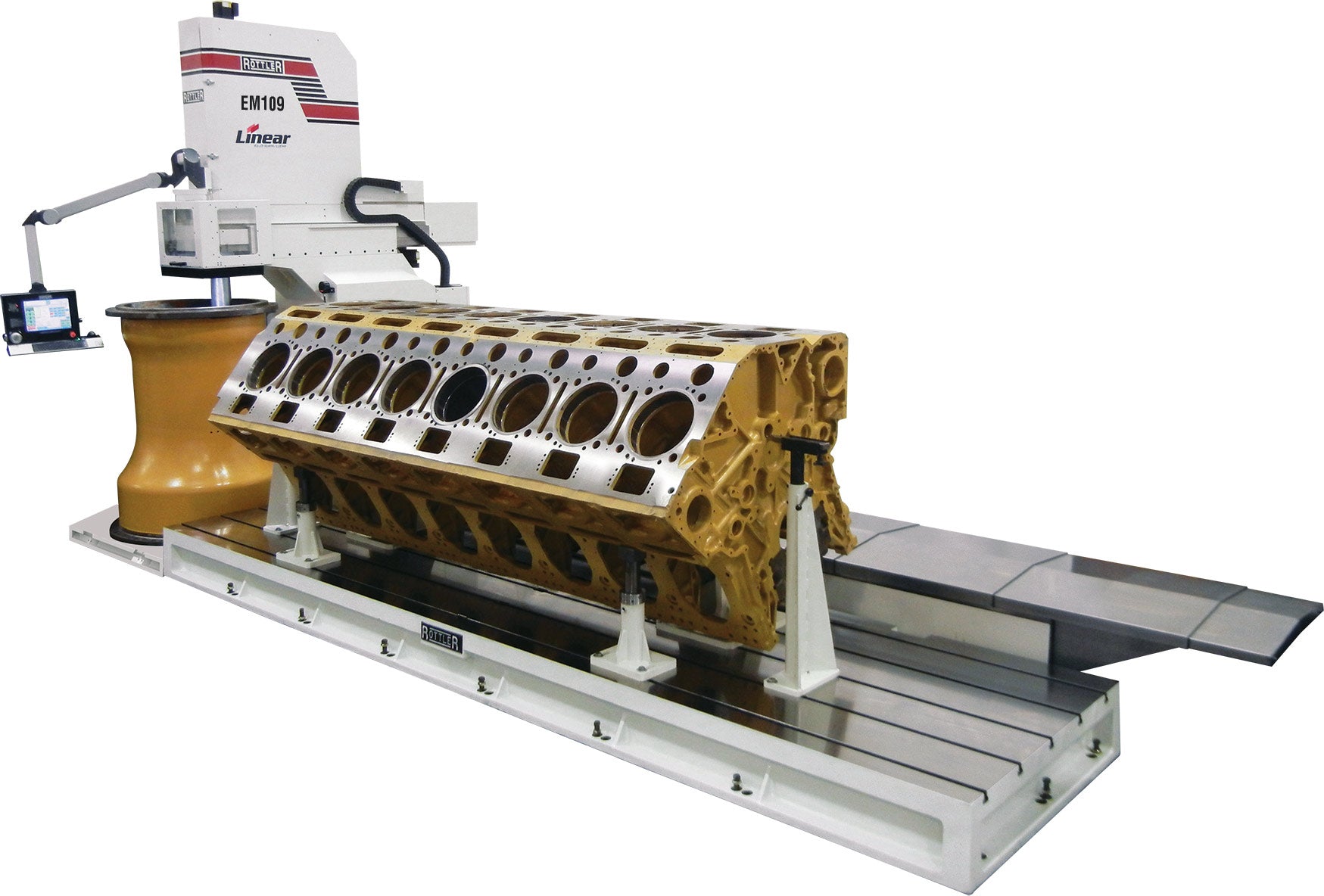

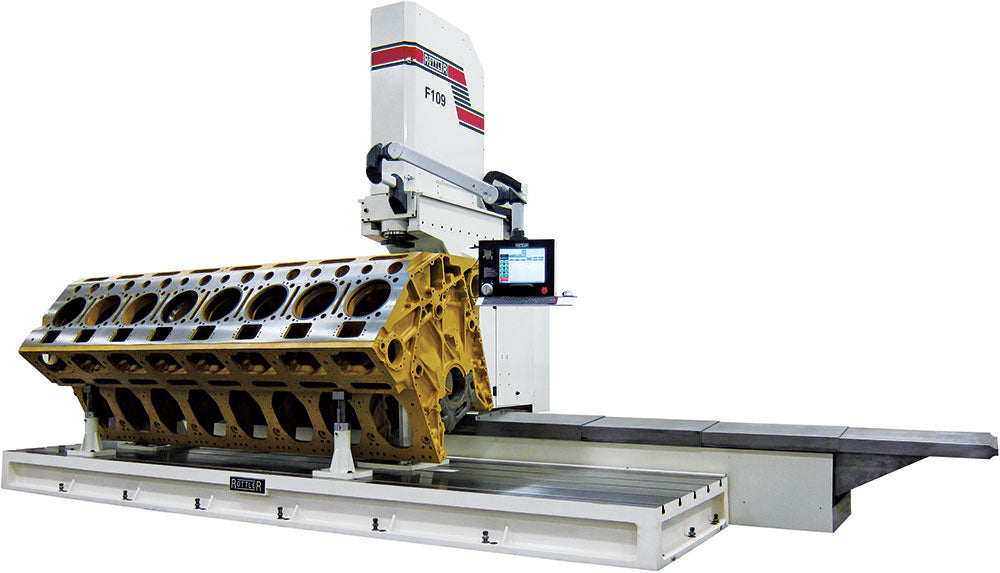

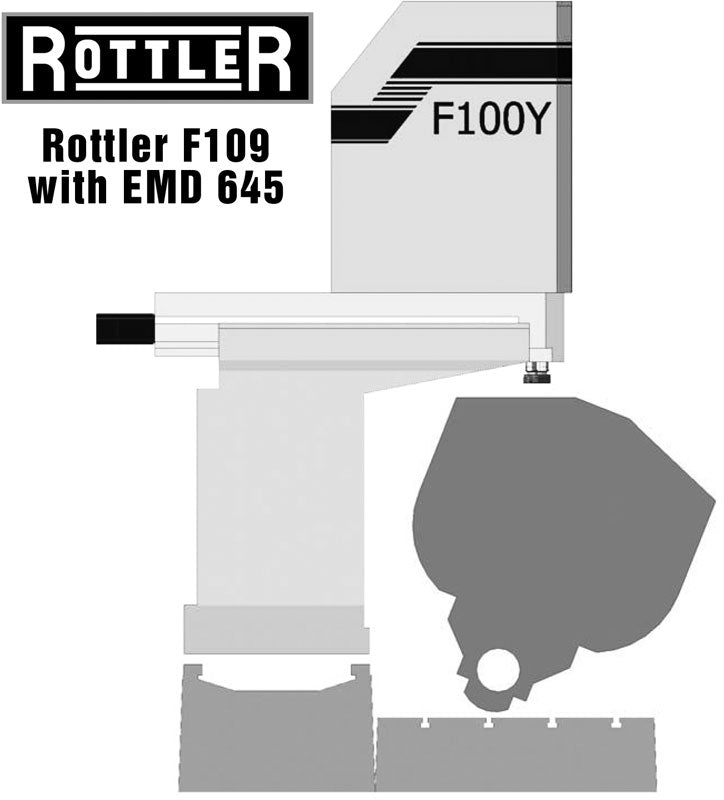

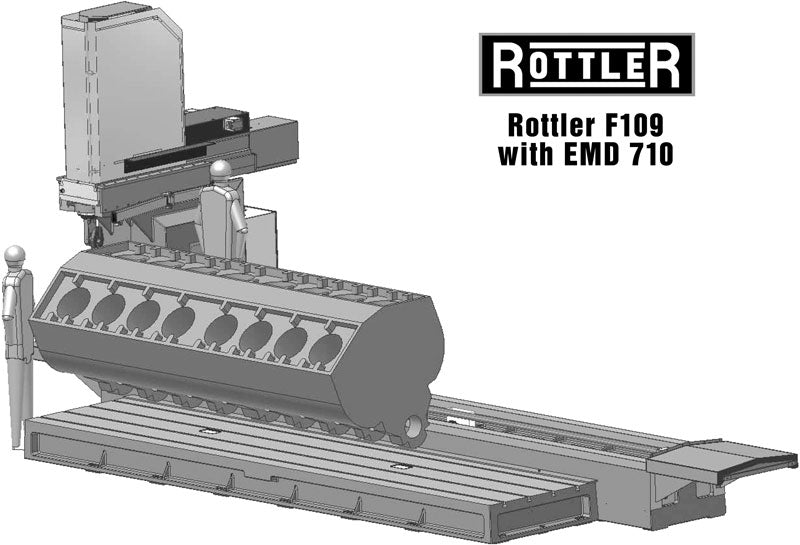

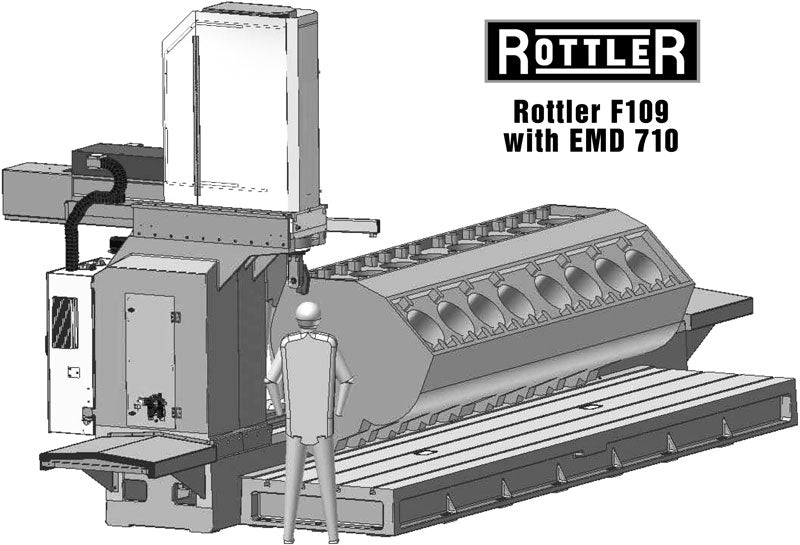

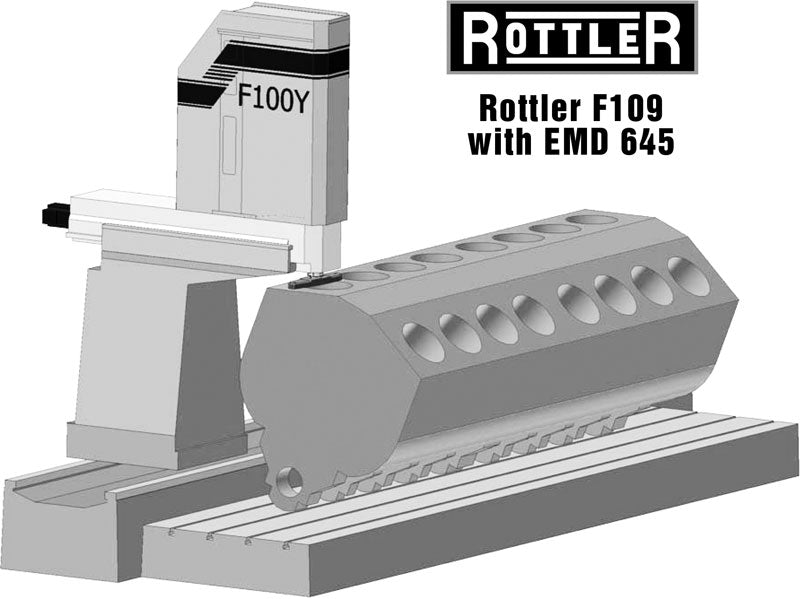

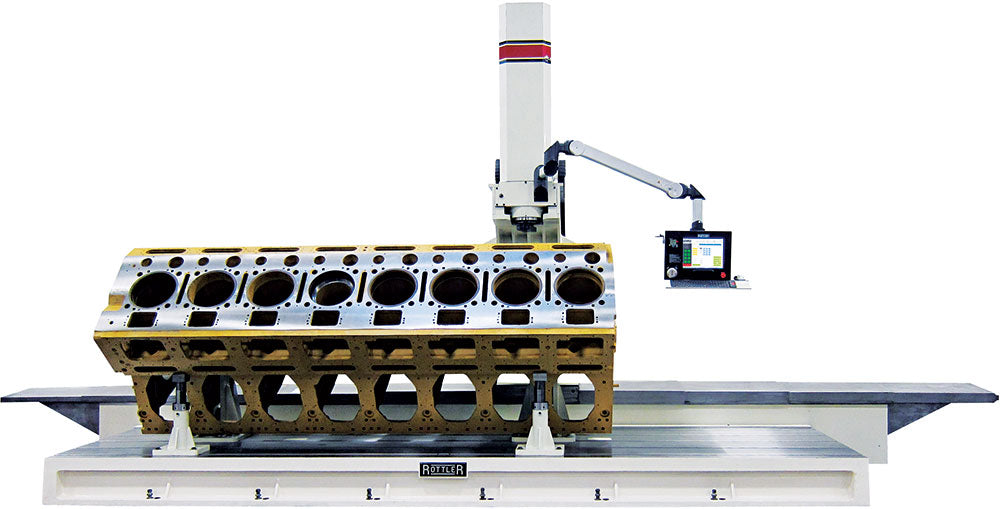

The EM109 F100 series machines are designed to boost productivity with features like quick tooling change-over, enabling boring and surfacing in a single setup. These versatile machines handle boring, surfacing, line boring, and universal machining with precision, thanks to ball screw-driven traveling columns and AC servo motors. Optional automatic cycle software and production tooling let you run complete block banks unattended—simply start the cycle and focus on other tasks while the EM109 works efficiently on your project.

For B2B customers, please register here for EU VAT exemption.

EM109H

Sale price€0,00

CHARACTERISTICS

- CNC (Computer Numerical Control) Machine Using Windows Operating System and Industrial PC with Intel Processor.

- Programming and Control Thru A 15" (400mm) Computerized Touch Screen.

- Precision Position Display in .0001" (.002mm) Resolution

- Software Options Available for Programmable Automated Cycles Such as Boring, Surfacing, Lower Sleeve Offset Boring, Water Hole Repairs, Main & Cam Line Boring, General CNC Machine Work

- USB Flash Drive for File Transfer to and From Computer

- Internet connection to the machine computer must be provided for training support and service.

- Machine/Computer Can Operate In Either Inch Or Metric System

- High Torque Servo Spindle Motor – Continuous 1925 in.lbs - 220NM. Peak 5775 in.lbs - 652NM

- Spindle Rotation Speed - Infinitely Variable 0-1000RPM

- Hard Chromed Precision Spindle Diameter 6" (150mm) with High Speed Angular Contact Bearings

- SPINDLE TAPER - HSK80A QUICK CHANGE allows Automatic Tool Changing System

- DIRECT DRIVE 3 Axis Movement by Precision Ball Screws & AC Servo Motors - Infinitely Variable

- Horizontal Movement (X Axis) - Left and Right Direction - 248" (6300mm)

- Horizontal Movement (Y Axis) - In and Out Direction - 24" (610mm)

- Vertical Movement (Z Axis) - Up and Down - 36" (915mm)

- Vertical, Horizontal and Spindle Load Monitoring for Fast Overload Shut Down

- Electronic Hand Wheel for Manual Movement – Per Click: Coarse Mode .01" (.25mm) Medium Mode .001" (.01mm) Fine Mode .0001" (.002mm)

- Infinitely Variable Feedrates Adjustable by Hand Wheel During Automatic Cycles

- Fast Rapid and Jog Speeds for Reduced Cycle Time

- Automatic Work Head Tilt System for Back Clearance During Surfacing

- Air Assisted Quick Change Cutterhead Draw Bar System

- Heat Treated Mehanite Cast Iron Machine Castings

- Air Pressurized Column for Less Friction and

- Accurate Positioning

- Turcite Coated Slideways for Low Friction and Extended Life

- Automatic Central Lubrication System Monitored by Computer

- Chip Guard vertically adjustable with 2 LED work lights

- Operation, Programming and Spare Parts Manual -Digital

- Paint Color Code: RAL9002 (Grey White)

MACHINEPARTS

- Control: Automatic

- Touch Screen: 381mm

- Table - Size: 1700 x 6100mm

- Table - T Slots: 4

- Travel - Horizontal (X Axis): 6300mm

- Travel - In/Out (Y Axis): 600mm

- Travel - Vertical (Z Axis): 915mm

- Travel - Spindle Nose to Table: 1716mm

- Travel - Spindle Center to Column: 1100mm

- Spindle - Rotation Speed: 0 to 1000 RPM

- Spindle - Motor: 12.75 Kw

- Cylinder Bore Range (with Optional Cutterheads): 19 - 500mm

- Line Bore Range (with Optional Cutterheads): 50 - 300mm

- Surfacing Cutterhead Diameters: 250, 340, 460 & 575 mm

- Dimensions - Floor Space Requirements: 3300D x 9200Wmm

- Machine Weight: 22500 kg

- Electrical Requirement: 220V, 60A, 50/60Hz, 3Ph

- Air Requirements: l/min @ 6 bar

- Paint Color Code: RAL9002 (Grey White)