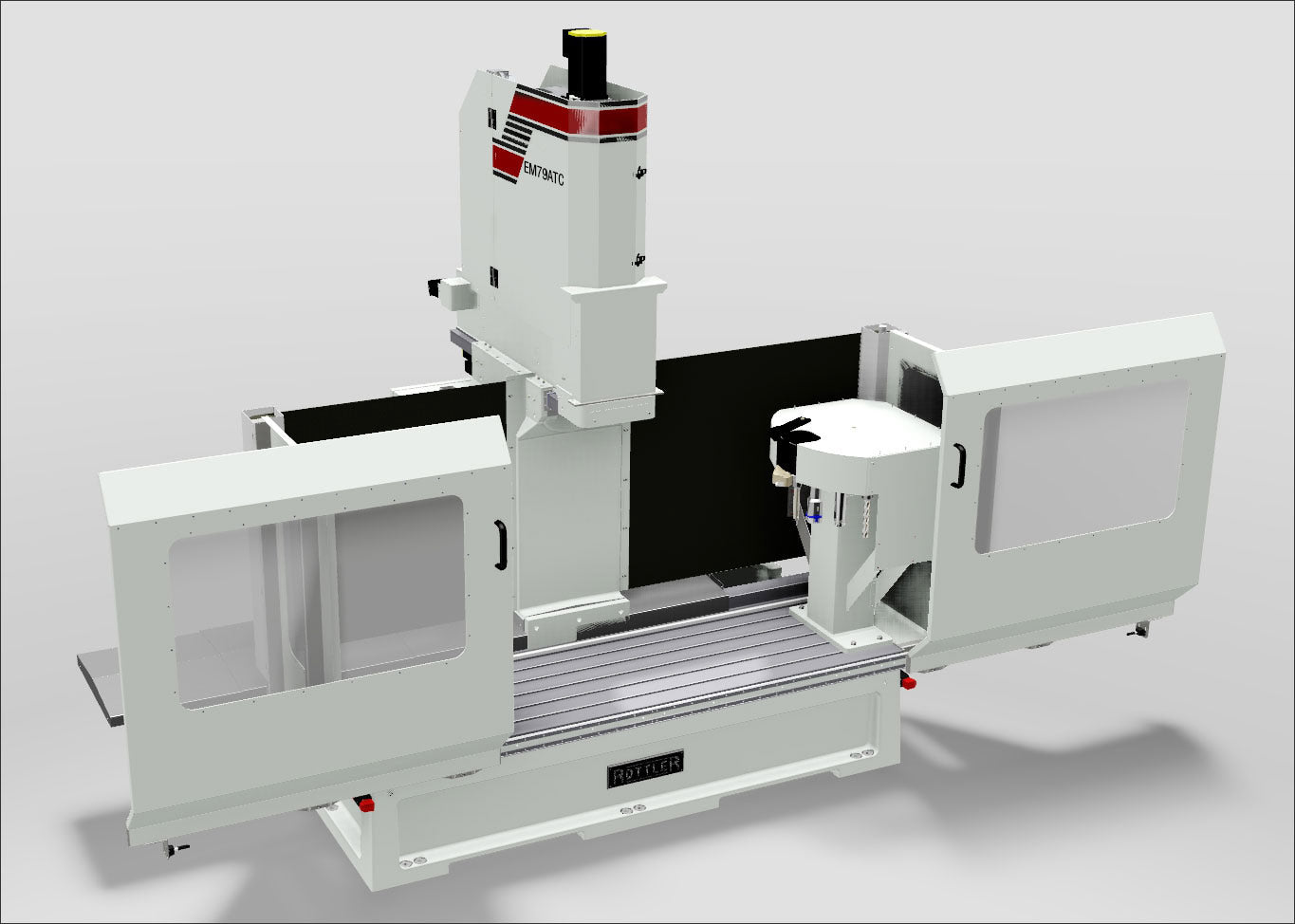

EM79ATC

The Rottler EM70 Series are designed for the small - medium size diesel engine rebuilder as well as the performance engine builder. The EM79ATC features an Automatic Tool Changer.

Rottler’s totally new, next generation CNC control found in the EM Series machines continues to give users unmatched speed of learning and ease of use when probing/digitizing without the need of additional cumbersome and expensive software. This advanced 4C software lets users know they are machining with the most state-of-the-science equipment available. Read more in the 'Control' tab below.

Features

-

Windows Touch Screen Operating System – Rottler uses Windows Touch Screen Technology on a 19" touch panel. The Windows software has many advantages such as it's common user interface that is easy to learn and fast to operate.

-

Instant Internet Support - Rottler offers cutting edge internet support direct from your machine to the factory. Skype is installed for internet support. This feature gives you instant, direct contact with Rottler right on the machine without even making a phone call.

-

Automatic Tool Changer - Automatic Tool Changing System available for production machining applications.

-

Traveling Column Design - Allows stationary work piece for increased accuracy.

-

Extra Height Capacity - Easily handle medium size diesel blocks forincreased versatility.

-

Large Turcite Coated Box Ways - Turcite coated bedways for reduced friction, longer life and better accuracy.

-

Extra Long T-slot - Work Table for dual workstations and increased versatility

-

World Standard CAT40 Spindle - For fast tool changing and worldwide versatility. Sliding Quill Spindle Design - For deep hole machining required for block work.

-

Servo Motors - Offer maximum torque and performance throughout the RPM range for precise accuracy and increase productivity.

-

Single Phase 208-240V - For power efficiency that saves electrical running costs.

-

Automated Workhead Tilting System - Provides superior surface finish.

-

Extra Long T-slot Work Table - for Dual Workstations and Large Blocks for increased versatility.

- Direct Drive Precision Ball Screws - Give long trouble free life and accurate movement.

Control

Rottler Exclusive Touch Screen Programming

The conveniently located control pendent centralizes the machine controls. Only the buttons and interactive menus required for a particular machine operation are displayed. Machine operations can easily be done manually or automatically, with the ability to store programs in memory. Digital readout allows the operator to accurately monitor position at all times. Control operates in metric and inch systems.

Fully Programmable Cycles

Conversational 3 axis CNC control, PC based with Windows Operating System.

Dimensions and Control through Touch Screen:

- Program Bore Centers, Exact Depth, Speed, Feed, etc.

- Machines complete bank or main line in Automatic Cycle.

- Lower Offset Boring allows lower sleeve repair in Automatic Cycle.

- Circular Interpolate Counterbores for Radius Undercut or Wide Counterbores.

- Surfacing/Milling – Multiple Pass – program for Rough Cut and Finish Cut for superior surface finish.

- Line Boring – program the bearing bores and length of each bore and the machine automatically moves from bore to bore, completing the line unattended.

- Face Main Line Thrust Faces square to centerline of Crankshaft using Rottler Circular Interpolation software.

For B2B customers, please register here for EU VAT exemption.