- Electric installation 24 V

- Hydraulic installation

- Cooling installation with tank

- Two self centering chucks

- Pair of additional counter weights

- Grinding wheel with pair of wheel hubs

- Narrow steady rest

- Wheel periphery and side truing attachment with diamond

- Eccentricity control device with dial gauge

- Truing fixture for checking concentricity with dial gauge

- V-square for centering of crankpins with dial gauge

- Wheel balancing mandrel

- Motor drive pulley for reduced wheel diameter

- Grinding wheel stripper

- Set of steel splash guards

- Service spanners

- Operating manual

- Set of steel splash guards

- Service spanners

- Operating manual

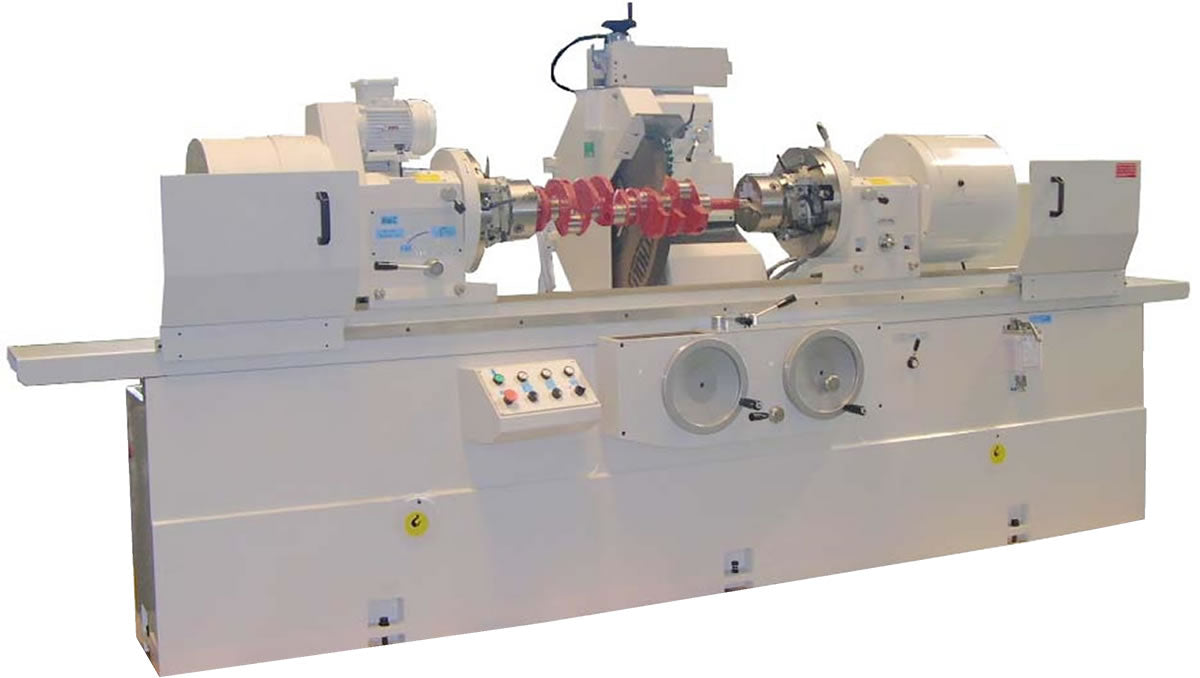

REX 1500

The Rex 1500 is a robust and high-precision crankshaft grinding machine designed for the reconditioning and manufacturing of crankshafts. It combines strength, precision, and user-friendly operation, making it an ideal solution for engine rebuilders and workshops requiring consistent quality and high performance.

Equipped with advanced hydraulic systems, precision measuring tools, and a comprehensive set of standard accessories, the Rex 1500 ensures reliable operation and outstanding grinding accuracy. Its versatile setup capabilities allow for the machining of a wide range of crankshaft sizes and geometries, making it suitable for both small and medium-sized engines.

Standard Equipment

-

24 V electric installation

-

Hydraulic system

-

Cooling system with tank

-

Two self-centering chucks

-

Pair of additional counterweights

-

Grinding wheel with pair of wheel hubs

-

Narrow steady rest

-

Wheel periphery and side truing attachment with diamond

-

Eccentricity control device with dial gauge

-

Truing fixture for checking concentricity with dial gauge

-

V-square for crankpin centering with dial gauge

-

Wheel balancing mandrel

-

Motor drive pulley for reduced wheel diameter

-

Grinding wheel stripper

-

Set of steel splash guards

-

Service spanners

-

Operating manual

Technical Specifications

Distance between centers: 1550 mm

Distance between chucks: 1540 mm

Center height over table: 250 mm

Swing over table: 500 mm

Maximum offset of centers: 100 mm

Maximum grinding diameter: 180 mm

Fast hydraulic wheelhead traverse: 110 mm

Hand micrometric wheelhead feed: 150 mm

Micrometric feed graduation: 0.005 mm

Wheelhead feed per reverse: 1 mm

Hand micrometric worktable traverse per reverse: 11 mm

Fast hydraulic worktable traverse: 3 m/min

Grinding wheel speed: 900–1000 rpm

Maximum grinding wheel diameter: 710 mm

Grinding wheel width (min.–max.): 19–50 mm

Chuck diameter: 180 mm

Chuck holding diameter: 220 mm

Steady rest capacity: 30–100 mm

Workhead spindle speeds: 20–60 rpm

Maximum weight between centers: 200 kg

Maximum weight on rests: 500 kg

Machine dimensions (L × W × H): 3.9 × 1.5 × 1.7 m

Approximate net weight: 3300 kg

For B2B customers, please register here for EU VAT exemption.

CHARACTERISTICS

Standard Equipment

MACHINEPARTS

- Distance between centers: mm 1550

- Distance between chucks: mm 1540

- Height of centers over table: mm 250

- Swing over table: mm 500

- Offset of centers: mm 100

- Grinding diameter: mm 180

- Fast hydraulic wheelhead traverse: mm 110

- Hand micrometric wheelhead feed: mm 150

- Hand micrometric wheelhead feed graduation: mm 0,005

- Whellhead feed per reverse: mm 1

- Hand micrometric worktable traverse per reverse: mm 11

- Fast hydraulic worktable traverse: m/ min 3

- Grinding wheel speeds: rpm 900-1000

- Grinding wheel diameter: mm 710

- Width of grinding wheel (min – max): mm 19-50

- Diameter of chucks: mm 160

- Chucks holding diameter: mm 220

- Rest capacity: mm. 30 -100

- Workhead spindle speeds: r.p.m. 20 – 60

- Max. weight on centers: Kg. 200

- Max. weight on rests: Kg. 500

- Lenght x width x height: m. 3.9 x 1.5 x 1.7

- Approx. net weight: Kg. 3300