S85A

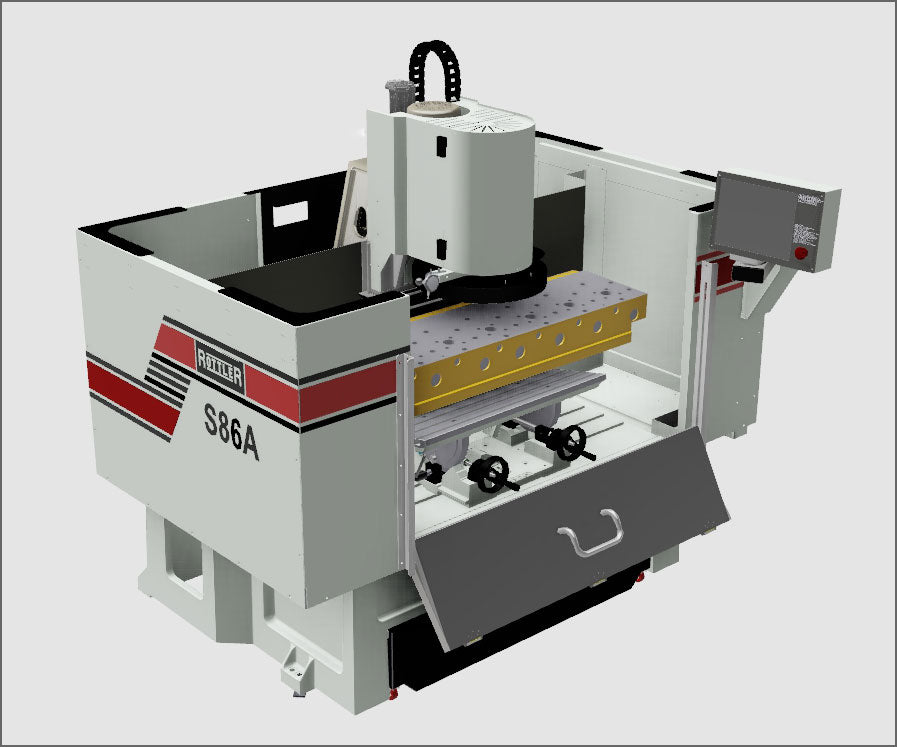

Traveling column design proven for decades in Rottler engine block machining centers reduces floor space requirements and improves accuracy of surface finish.

The S85A is ideal for a job shop that does a wide variety of engines including diesel.

The S85A model is designed for surfacing from the smallest to automotive and small diesel heads and blocks. The S85A is ideal for the requirements of the performance racing engine builder and production engine remanufacturer.

The programmable downfeed with multiple passes is ideal when large amounts of material need to be removed in one set up. Angle milling and weld removal are also easily done in one cycle.

Direct Drive Ball Screws and Linear Roller Bearing Slideways on vertical and horizontal movements combine to give precise motion control resulting in precision surface finish.

Full Steel Enclosure surrounds the machine and keeps the work area clean and free of chips and protects operators from moving machine parts.

Electrical Enclosure mounted on the side of the machine allows the back of the machine to be installed against a wall reducing floor space requirements.

The S85A is ideal for a job shop that does a wide variety of engines including diesel.

The S85A model is designed for surfacing from the smallest to automotive and small diesel heads and blocks. The S85A is ideal for the requirements of the performance racing engine builder and production engine remanufacturer.

The programmable downfeed with multiple passes is ideal when large amounts of material need to be removed in one set up. Angle milling and weld removal are also easily done in one cycle.

Direct Drive Ball Screws and Linear Roller Bearing Slideways on vertical and horizontal movements combine to give precise motion control resulting in precision surface finish.

Full Steel Enclosure surrounds the machine and keeps the work area clean and free of chips and protects operators from moving machine parts.

Electrical Enclosure mounted on the side of the machine allows the back of the machine to be installed against a wall reducing floor space requirements.

For B2B customers, please register here for EU VAT exemption.

S85A

Sale price€0,00

CHARACTERISTICS

- Latest ClearPath Integrated Servo Control Technology - State of the art electronic controls make the S80 machines the most advanced dry cutting surfacing machines available today.

- Increased Vertical Travel – the workhead is mounted on linear roller bearing slideways and has extended travel 19” (483mm) eliminating the need for parallels while being able to surface a wide variety of jobs from small single cylinder heads to tall diesel blocks.

- Linear Roller Bearing Slideways – the vertical and horizontal movements are by precision ball screens and on linear roller bearing slideways.

- Super Fine Surface Finish – Direct Drive precision ball screws and linear slideways combined with infinitely variable speeds and feeds allows surface finish as low as 2Ra to 6Ra. Today's MLS (Multi Layer Steel) head gaskets require super fine finish to seal combustion pressure and oil and water.

- Dry Cutting – the spindle and cutterhead system is specially designed and developed for dry cutting with CBN and PCD cutting tools eliminating the need for coolant.

- Chip Collection System - the base casting and machine enclosure is designed to catch chips and direct them down into a roll out chip bin making clean up fast and easy.

- Reduced Floor Space – Traveling Column Design and compact, one piece base castings give the most compact surfacing machines available today reducing floor space requirements.

- Folding Doors – the stainless steel doors fold down for access to the work area and fold up to protect the operator and keep the work area clean of any chips.

- Universal T Slot Base – Large One Piece Mehanite Cast Iron Base with T-Slots allows mounting of any fixture and any job - jacks and clamps can be placed anywhere!

- Program Length of Part – Input length of surface to be machined and the machine travels the exact distance then returns to home – not necessary for time consuming setting of end stops.

- Fast Floor to Floor Time - Heads can be surfaced in a few minutes and a pair of angled V8 heads in less than eight minutes.

MACHINEPARTS

- New Technology ClearPath® Integrated Servo System with Touch Screen Control.

- Conversational Touch Screen Control allows simple programming for any workpiece such as depth of cut, multiple passes, total material removed, speeds and feeds.

- No Handwheel required, machine is moved by sliding finger on touch screen slide bars.

- Programmable Rapid Touch Off Set Point for reduced Cycle Times

- On completion of Automatic Cycle, Cutterhead returns to Home Start Position at Vertical Zero Height

- Infinitely Variable Spindle Speeds from 350 - 1,800 RPM for machining different metals

- Infinitely Variable Travel Feeds .001 - .080" (.025-2mm) per Cutterhead Revolution for Desired Surface Finish Roughness

- Work Head Vertical Travel via Ball Screw and Linear Roller Slideway for Precise Movement

- Maximum Work Head Horizontal Travel 41" (1,041mm)

- High Rapid Traverse Rate for Reduced Cycle Time - 200" (5,080mm) per minute

- Direct Drive Ground Ball Screw for Work Head and Vertical Column Traverse

- Linear Roller Bearing Slideways for Smooth and Precise Movement

- 14" (360mm) Cutterhead includes 2 radially and axially adjustable cutting insert tool holders for 3/8" (9.52mm) IC Round or Square inserts (Optional 1/2" (12.70mm) IC Cutting Insert tool holders available)

- Cutterhead Guard and Slanted Casting with Roll Out Chip Bin for Efficient Chip Collection

- Enclosed Work Area with Quick Folding Door for Easy Access and a Cleaner Work Environment.

- Depth Dial Indicator Assembly for Rapid Touch Off on Surface to be Machined

- Large One Piece Base Casting with 3 T Slots for Universal Fixture Mounting

- Instruction and Spare Parts Manual